1.The pump flow components of IS single stage single suck(axial)water centrifugal pump are made of high molecular-polyethylene(UHMWPE).UHMWPE has excellent corrosion resistance,excellent wear resistance(house of all kinds of plastic),impact resistance,resistance to the crystal.

2.This pump seal:mechanical seal,dynamic seal and packing seal,etc.

3.This pump can also convey the pulp containing solid makings and sewage containing various impurities

4.It shows good performance in the transmission of corrosive liquid containing fine granular and conveying hydrofluoric acid,hydrochloric acid,thin sulfuric acid,strong alkali,etc

5.The pump apply for-50°C to 80°C.Its applicable temperature is 120°C just when the impeller and pump body is replaced by other engineering plastic.

Detailed Product Description:

1.IS type pump is single grade single suck(axial)centrifugal pump.

2.It is to convey the liquid which work temperature less than 80°C,or the properties of physical and chemical similar to water.

3.Applicable to industrial and urban water supply,drainage and irrigation,etc.The material of wetted part is cast iron.

4.IS series water pump suitable for chemical,oil,petroleum chemical industry,metallurgy,light industry,printing,dyeing,pharmaceutical,environmental protection,sea water desalination,maritime oil,papermaking,foodstuff,etc.industrial departments.

5.They are used to transport chemical(containing not solid,organic or inorganic),oil products and corrosive medium of liquid.

Application:

a.Single stage Centrifugal Pump is suitable for transporting pure water or liquids with physical and chemical properties similar to pure water.

b.Suitable for urban water supply and water drainage.

c.Suitable for power stations.

d.Suitable for ceramics.

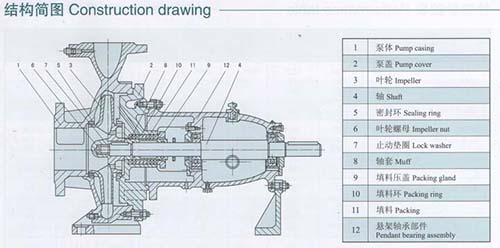

Construction Drawing

| IS-单级单吸清水离心泵 | |||||||||

| 型 号 | 流 量Q | 扬 程H (m) | 转 速N (r/min) | 功 率(KW) | 效 率 (%) | 叶轮名义直径 (mm) | 汽蚀余量(m) | ||

| (m3/h) | (l/s) | 轴功率 | 电机功率 | ||||||

| IS50-32-125 | 7.5 12.5 15 |

2.08 3.47 4.17 | 22 20 18.5 |

2900 | 0.96 1.13 1.26 | 2.2 | 47 60 60 |

130 | 2.0 2.0 2.5 |

| IS50-32-125A | 11.2 | 3.1 | 16 | 2900 | 0.84 | 1.1 | 58 | 116 | 2.0 |

| IS50-32-160 | 7.5 12.5 15 |

2.08 3.47 4.17 | 34.3 32 9.6 |

2900 | 1.59 2.02 2.16 | 3 | 44 54 56 |

158 | 2.0 2.0 2.5 |

| IS50-32-160A | 11.7 | 3.3 | 28 | 2900 | 1.71 | 2.2 | 53 | 148 | 2.0 |

| IS50-32-160B | 10.8 | 3 | 24 | 2900 | 1.41 | 2.2 | 50 | 137 | 2.0 |

| IS50-32-200 | 7.5 12.5 15 |

2.08 3.47 4.17 | 52.5 50 48 |

2900 | 2.82 3.54 3.95 | 5.5 | 38 48 51 |

198 | 2.0 2.0 2.5 |

| IS50-32-200A | 11.7 | 3.3 | 44 | 2900 | 3.16 | 4 | 45 | 186 | 2.0 |

| IS50-32-200B | 10.8 | 3 | 38 | 2900 | 2.60 | 3 | 43 | 173 | 2.0 |

| IS50-32-250 | 7.5 12.5 15 |

2.08 3.47 4.17 | 82 80 78.5 |

2900 | 5.87 7.16 7.83 | 11 | 28.5 38 41 |

250 | 2.0 2.0 2.5 |

| IS50-32-250A | 11.7 | 3.3 | 70 | 2900 | 6.47 | 7.5 | 35 | 234 | 2.0 |

| IS50-32-250B | 10.8 | 3 | 60 | 2900 | 5.51 | 7.5 | 32 | 217 | 2.0 |

| IS65-50-125 | 15 25 30 |

4.17 6.94 8.33 | 21.8 20 18.5 |

2900 | 1.54 1.97 2.22 | 3 | 58 69 68 |

130 | 2.0 2.5 3.0 |

| IS65-50-125A | 22.4 | 6.2 | 16 | 2900 | 1.47 | 2.2 | 66 | 116 | 2.0 |

| IS65-50-160 | 15 25 30 |

4.17 6.94 8.33 | 35 32 30 |

2900 | 2.65 3.35 3.71 | 5.5 | 54 65 66 |

165 | 2.0 2.0 2.5 |

| IS65-50-160A | 23.4 | 6.5 | 28 | 2900 | 2.83 | 4 | 63 | 154 | 2.0 |

| IS65-50-160B | 21.7 | 6 | 24 | 2900 | 2.35 | 4 | 60 | 143 | 2.0 |

| IS65-40-200 | 15 25 30 |

4..17 6.94 8.33 | 53 50 47 |

2900 | 4.42 5.67 6.29 | 7.5 | 49 60 61 |

200 | 2.0 2.0 2.5 |

| IS65-40-200A | 23.4 | 6.5 | 44 | 2900 | 4.92 | 5.5 | 57 | 188 | 2.0 |

| IS65-40-200B | 21.8 | 6.1 | 38 | 2900 | 4.13 | 5.5 | 55 | 175 | 2.0 |

| IS65-40-250 | 15 25 30 |

4.17 6.94 8.33 | 82 80 78 |

2900 | 9.05 10.89 12.02 | 15 | 37 50 53 |

254 | 2.0 2.0 2.5 |

| IS65-40-250A | 23.4 | 6.5 | 70 | 2900 | 9.10 | 11 | 49 | 238 | 2.0 |

| IS65-40-250B | 21.7 | 6 | 60 | 2900 | 7.51 | 11 | 47 | 220 | 2.0 |

| IS65-40-315 | 15 25 30 |

4.17 6.94 8.33 | 127 125 123 |

2900 | 18.5 21.3 22.8 | 30 | 28 40 44 |

315 | 2.5 2.5 3.0 |

| IS65-40-315A | 23.9 | 6.6 | 114 | 2900 | 19.41 | 22 | 38 | 301 | 2.5 |

| IS65-40-315B | 22.7 | 6.3 | 103 | 2900 | 17.19 | 22 | 37 | 286 | 2.5 |